what size for the cover tape and carrier tape?

What kind size of cover tape need go with difference width carrier tape like 8 mm, 12 mm, 16 mm, and 24 mm...?

1. Carrier Tape of 8 mm has to be used with Cover tape of 5.4mm.

2. Carrier Tape of 12 mm has to be used with Cover tape of 9.3mm.

3. Carrier Tape of 16 mm has to be used with Cover tape of 13.3mm.

4. Carrier Tape of 24 mm has to be used with Cover tape of 21.3mm.

5. Carrier Tape of 32 mm has to be used with Cover tape of 25.5mm.

6. Carrier Tape of 44 mm has to be used with Cover tape of 37.5mm.

7. Carrier Tape of 56 mm has to be used with Cover tape of 49.5mm.

8. Carrier Tape of 72 mm has to be used with Cover tape of 65.5mm.

9. Carrier Tape of 88 mm has to be used with Cover tape of 81.3mm.

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

Force-One is a manufacturer of protection film in Taiwan. Our Pressure Sensitive Adhesives PSA Cover Tape (SMT), Cold Seal Cover Tape, Top Cover Tape, of tape and reel have high quality, nice price and without any adhesive residue issues, it can fit what you want. Our cover tape made in Taiwan and have more than 20 kinds for our customers, like: anti-static type, difference adhesive force, difference color, anti-high temperature. We can customized what you need, welcome to contact us.

===Table of Contents===

1.Single side normal anti-static PSA cover tape.

2.Double side high anti-static PSA cover tape.

3.Process Introduction for Cover Tape

=======================

Single side normal anti-static PSA cover tape (Normal Type)

EX: PSA-608D、PSA-608AS

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

The Benefits of Force-One's Cover Tape:

1.PET with Pressure Sensitive Adhesives combined with brown or Transparent anti-static film.

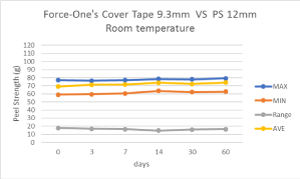

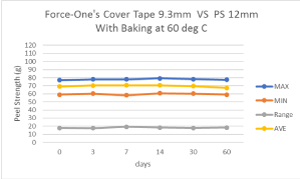

2.Excellent and stable quality . The aging (60℃ / 720 hrs) and peeling force test had passed.

3.The value of anti-static is 10^9~11, It can prevent ESD issue.

4.Excellent sealing. Can meet any carrier tape of PC, PS, PET to seal.

5.Thickness: 60 ± 5 um. Can anti high temperatures before vacuum packaging ( 80℃) without peeling issue.

6.Complies with EIA-481 standards

Anti-static PSA Cover Tape(Heat-Resisting Type)

EX: PSA-608G

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

Force-One's PSA-608G is high anti-static, the function is better than 3M Pressure Sensitive Cover Tape 2668 and 2698. 3M 2668 and 2698 just have single side and high anti-static. Force-One PSA-608G has double side and high anti-static. It can protect IC, WLCSP, LEDs and ultra-small and lightweight packages to anti Electrostatic discharge (ESD). Force-One PSA-608G also has good and stable peeling strength to avoid the components jumping issue.

The Benefits of Force-One's Cover Tape:

1.PET with Pressure Sensitive Adhesives combined with brown or Transparent anti-static film.

2.Excellent and stable quality. The aging (60℃ / 720 hrs) and peeling force test had passed.

3.The value of anti-static is 10^9~10^11, Adhesive is 10^8~10 It can prevent ESD issue.

4.Excellent sealing. Can meet any carrier tape of PC, PS, PET to seal.

5.Thickness: 60 ± 5 um. Can anti high temperatures before vacuum packaging (120℃) without peeling issue.

6.Complies with EIA-481 standards

Force-One produce many kind of PSA cover tape. Our PSA cover tapes have very stable peeling strength for PS or PC carrier tape. Our PSA cover tapes have good anti-static function. We can help the

Want to know more, Welcome to Contact us

Read About "Heat Seal Cover Tape"

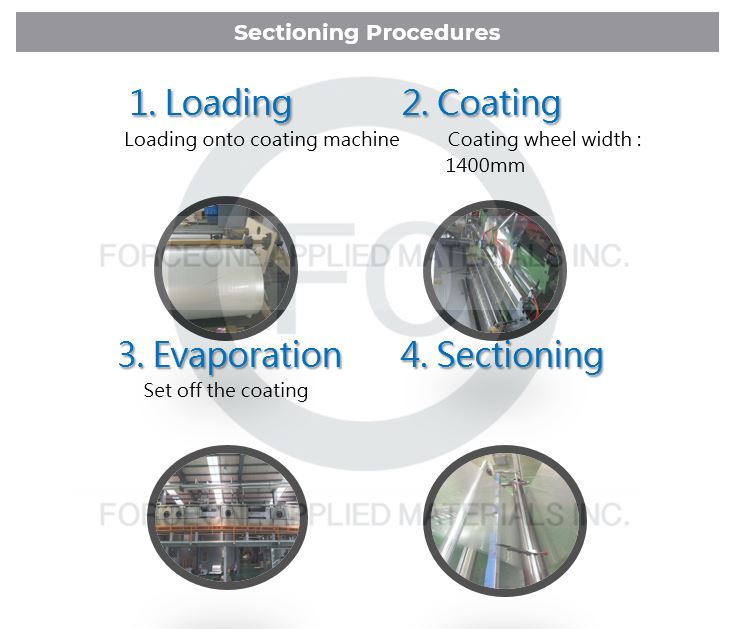

===Process Introduction for Cover Tape===

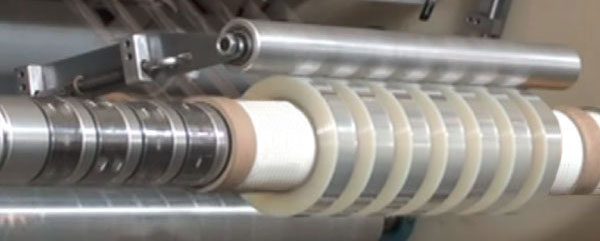

>Coating Line:

>Cutting Line:

===The Introduction of Force-One's Cover Tape===

Force-One's is uniquely designed to peel through the film itself and available as static dissipative.The cover tapes for semiconductor(IC) or Passive components seal electrical and electronic components into Carrier Tapes, it have anti-static layers can anti-static(ESD) during packing, transport and storage. The cover tapes for semiconductor could combine excellent sealing properties with smooth peel force to protect IC or Passive components and permit efficient pick-and-place operations. The full line of Force-One's Cover Tapes includes conductive, non-conductive and static dissipative products with heat activated or pressure-sensitive adhesive.

Both PSA and HAA cover tapes can be found in non-conductive and static-dissipative versions. Some cover tapes are termed anti-static which are usually perceived as being the same as static-dissipative cover tapes. Technically, anti-static refers to a material which does not generate a static charge when rubbed against a second material (triboelectric charging). Static dissipative refers to a material which can bleed off a charge through the mechanism which provides it’s surface resistivity. A non-conductive material is defined as having a surface resistivity (Rs) greater than 10^12 ohms/square. Static dissipative material is defined as having a surface resistivity (Rs) between 10^5 ohms/square and 10^12 ohms/square. While conductive material is defined as having a surface resistivity (Rs) of less than 10^5 ohms/square.

The cover tapes(Tape & Reel) for semiconductor(IC) or Passive components is good for SMD/SMT(Surface-Mount Device / Surface-Mount Technology) process. And can anti-static cover tape for packaging of surface mount devices (ESD protection).

Common trS: Thin:0.05~0.06 mm ; Transmittance: 60%~89% ; Haze: 3%~30% ; Anti-static: ≦10^9-11Ω/sq ; Working temperature:140℃ - 190℃ ; RA pass:55℃~60℃/720 hrs

Width: 5.4mm, 9.3mm, 13.3mm, 21.3mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm, 81.5mm

◆Heat Activated (HAA)

1. Normal Type

2. Transparent Type

3. Conductive Type

Read More About "Heat Activated Cover Tape"◆Pressure Sensitive Adhesives Sensitive (PSAs)

1. Normal Type

2. Conductive Type

3. Heat-Resisting Type

Read More About "PSA Cover Tape"Want to know more, Welcome to Contact us

*****Sealing Heat Activated Cover Tape*****

For any heat-activated adhesive cover tape, as a general rule,increasing temperature, dwell time, and pressure on a given sealing machine will, within limits, increase adhesion (peel). However, for most of the HAA cover tapes available in the marketplace today, temperature and dwell will have a greater affect on adhesion than pressure. The ways these variables interact in the sealing process are of interest to anyone trying to control a packaging process.

>Normal Type Cover Tape

Similar as Common trS

>Transparent Type Cover Tape

Special trS: Transmittance: 89%

>Conductive Type Cover Tape

Special trS: PET's anti-static: ≦10^5-10Ω/sq ; Adhesive anti-static: ≦10^9Ω/sq

*****Pressure Sensitive Adhesives PSA Cover Tape*****

PSA cover tapes require different processing and handling than heat activated cover tapes and are generally considered to be easier to seal than their heat activated counterparts. The PSA adhesive is a synthetic adhesive formulated to remain tacky over a wide range of temperatures, including room temperature. Hence, PSA cover tapes don't heat to seal them with carrier tape. To prevent components from sticking to the adhesive, a liner film is added to cover the adhesive in the center portion of the cover tape. PSA cover tapes are slightly more complex in their cons.

>Normal Type-Cover Tape

Similar as Common trS

>Conductive Type Cover Tape

Special trS: Adhesive anti-static:≦10^3-5Ω/sq

>Heat-Resisting Type Cover Tape

Special trS: Can Heat-Resisting: 125℃/8hr or 50℃/24hr

Read More About "PSA Cover Tape"